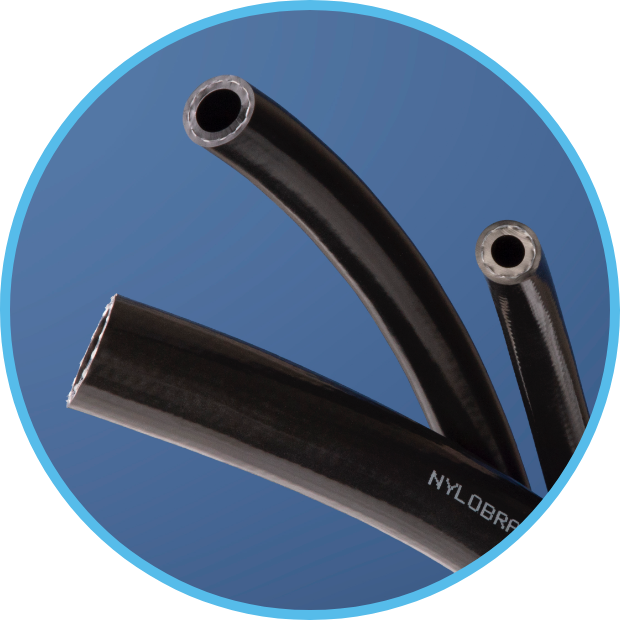

Nylobrade® Push-On Braid

Reinforced Opaque Hose

Features

- A blend of nitrile rubber and PVC reinforced with polyester

- Specially designed for use with Push-On style barbed fittings which eliminate the need for clamps

- Non-marking cover, resistant to UV, ozone, and abrasion

- Electrically non-conductive

- Offers cold temperature flexibility

- Well suited for air and water lines and outdoor use

- Silicone free — use as air hose in paint applications

- Lighter weight and more abrasion resistant than all-rubber, push-on style hose

Applications

Chemical Transfer • Coolant Lines • Filling Lines • Hydraulics • Instrumentation Lines • Material Handling • Pneumatics • Spray Systems • Air Lines • Water & Fluid Lines

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore A ±5

Tensile Strength, psi

Ultimate Elongation, %

100% Modulus of Elasticity, %

Brittle Temperature

Max. Operating Temperature, °F

(when used with appropriate clamps)

75

1800

350

1200

-35

150

**Values listed are typical and are meant only as a guide to aid in design. Field testing should be performed to find the actual values for the application.

Notes

Nylobrade Push-On Hose may be used up to 200 psi at 68°F. Elevated temperatures require in-field testing to determine suitability for use without clamps.

The opaque black color of Nylobrade Push-On Hose helps hide dirt and scuff marks.

Click here to review the PVC Products – Material & Regulatory Summary

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

| Part Number | ID (in.) | OD (in.) | Wall (in.) | Working PSI (at 68°F) | Bend Radius (in.) | Weight (lbs./100 ft.) |

|---|---|---|---|---|---|---|

| 4310054 | .260 | .500 | .120 | 200 | 2.5 | 8 |

| 4310068 | .318 | .570 | .123 | 200 | 3.2 | 10 |

| 4310082 | .385 | .630 | .120 | 200 | 3.85 | 11 |

| 4310110 | .510 | .750 | .120 | 200 | 5 | 14 |

| 4310138 | .635 | .880 | .120 | 200 | 6.25 | 17 |

| 4310166 | .765 | 1.040 | .133 | 200 | 7.5 | 20 |

Standard coil length is 100 ft. Add length suffix to part number when ordering.

Example: 100 ft. of 1/4” I.D. x 1/2” O.D. tubing is part number 431 0054-100. Working pressures are calculated from burst testing using a 4:1 safety factor. Application testing is recommended.

[ID] is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.