Markets We Serve

Industrial

Achieve durable finished products with equipment made for industrial use, from agriculture to waste handling.

Learn More

Food & Beverage

Get the products you need right off the shelf to support a wide range of food and beverage applications.

Learn More

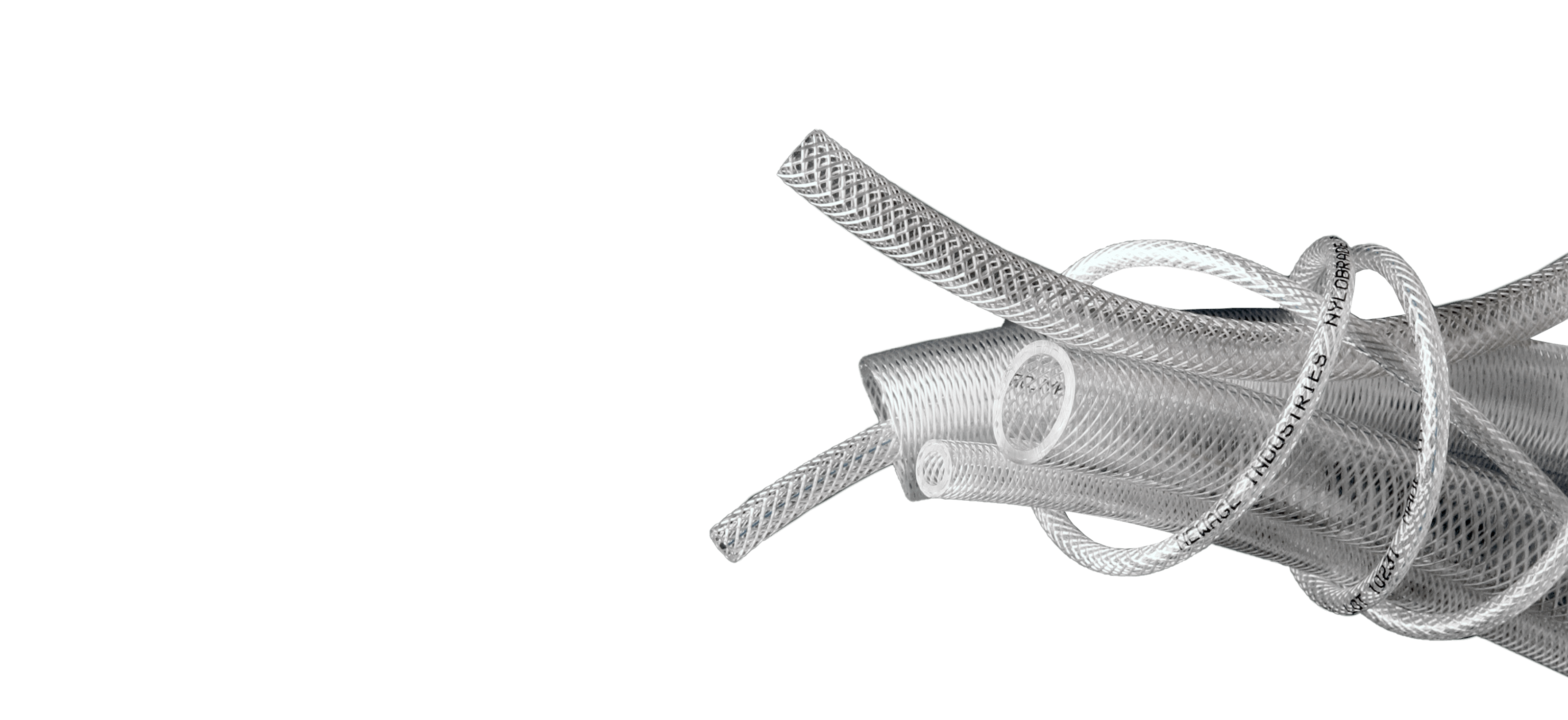

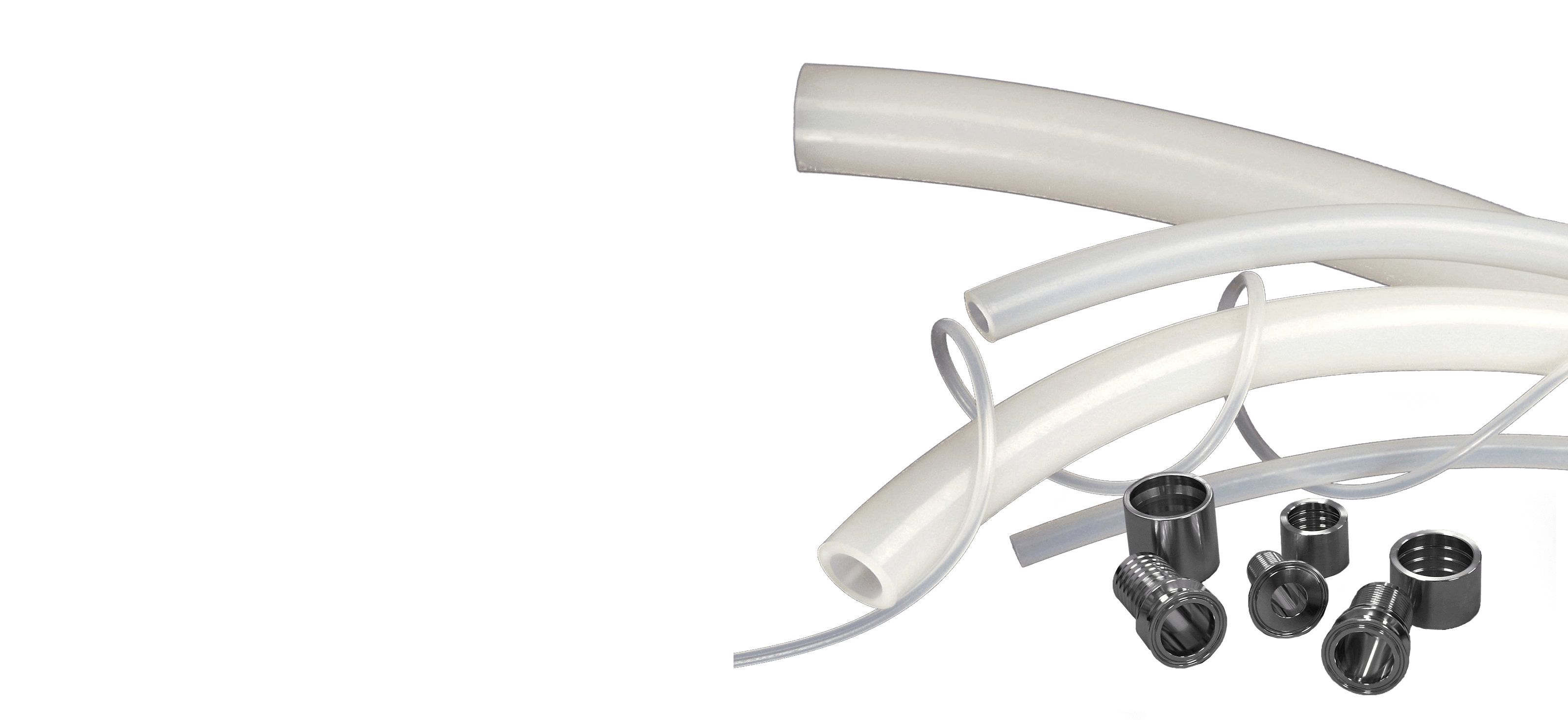

Quality Products from a Single Source

Find the right solution for standard and high-purity applications from a trusted single-source provider of durable thermoset and thermoplastic tubing and hose for a variety of industries.

Exceptional

Customer Experience

Share your project needs, see samples up close, and work closely with a responsive team that can meet your specs and make product adjustments with expert engineering capabilities.

Contact Our TeamCulture of Social Responsibility

Partner with a 100% employee-owned and Certified B Corporation™ company whose culture is built around making a positive impact on companies and communities through both product and process.

About Newage100% Employee Owned

Solar Powered Operations

Zero Landfill Commitment

Millions of Feet of Tubing in Stock

Forefront of COVID-19 Response