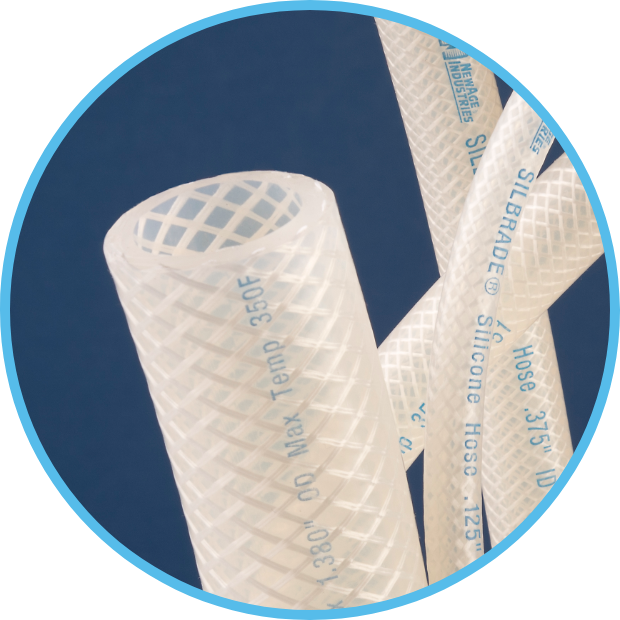

Silbrade® Braid Reinforced

Silicone Hose

Features

- Open mesh polyester braiding incorporated within the walls of silicone tubing

- Designed for elevated pressure applications

- Odorless, tasteless, and inert

- Able to resist extreme temperature variation: -99°F to 350°F

- Raw materials meet FDA requirements per FDA 21 CFR 177.2600 for use with food contact surfaces

- Listed by the National Sanitation Foundation (NSF-51) for food equipment materials

- Free of BPA, latex and phthalates; RoHS compliant

- Reusable and will withstand repeated sterilization^

- Translucent natural color for visual contact with the flow

- Excellent weatherability properties to resist UV, ozone, gases, moisture, and extreme temperatures

Applications

Beverage Service • Bottle Filling • Chemical Feeds • Deionized Water Transfer • Fermenter Lines • Hot Fill Lines • Food Handling • Laboratory • Resin Feeds • Stirring Vessels

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore A ±5 - Liner

Hardness, Shore A ±5 - Cover

Tensile Strength, psi

Elongation at Break, %

Tear Strength, Die B, ppi

Modulus at 100 %, psi

Brittle Temperature, °F

Max. Operating Temperature, °F

70

60

1460

320

100

415

-99

350

Notes

The construction of SILBRADE enables silicone tubing to handle increased pressure applications. SILBRADE offers outstanding resistance to temperature extremes and is made from raw materials that meet FDA requirements.

The flexible design and construction of SILBRADE also allows excellent bend radii and permits installation in restricted spaces without impeding flow.

SILBRADE, a peroxide-cured product, contains no sulfur or other acid-producing chemicals thereby eliminating the possibility of staining, corroding, or deteriorating other materials it contacts. It is also resistant to ozone and UV over long time periods.

^SILBRADE may be low pressure steam sterilized in-line or autoclaved at up to 250°F in a normal autoclaving cycle. However, if exposed to repeated steam sterilization or long-term high temperature or pressure, silicone will eventually relax and become gummy. It should then be replaced.

SILBRADE is not recommended for implantable or in-body uses or for continuous steam applications.

Care is recommended in the selection of fittings and clamps, as sharp barbed fittings or unlined metal clamps could tear into the hose wall and possibly cause a failure, especially at elevated pressures.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

| Part Number | Note | ID (in.) | OD (in.) | Wall (in.) | Available Lengths (ft.) | Working PSI (at 70°F) | Colors | Weight (lbs./100 ft.) |

|---|---|---|---|---|---|---|---|---|

| 2900072 | .125 (1/8) | .365 | .120 | 100 | 233 | Natural | 5 | |

| 2900149 | .188 (3/16) | .447 | .130 | 100 | 216 | Natural | 7 | |

| 2900226 | .250 (1/4) | .520 | .135 | 100 | 208 | Natural | 9 | |

| 2900303 | .313 (5/16) | .592 | .140 | 100 | 183 | Natural | 11 | |

| 2900380 | .375 (3/8) | .655 | .140 | 100 | 166 | Natural | 13 | |

| 2900457 | .500 (1/2) | .800 | .150 | 50, 100 | 141 | Natural | 17 | |

| 2900534 | .625 (5/8) | .965 | .170 | 50 | 116 | Natural | 23 | |

| 2900611 | .750 (3/4) | 1.100 | .175 | 50 | 91 | Natural | 28 | |

| 2900765 | [B] | 1.000 | 1.380 | .180 | 25, 50 | 75 | Natural | 36 |

Cut coils are available; charges do apply — call for details.

Add length suffix to part number when ordering.

Example: 100 ft. of 1/8″ I.D. x .365″ O.D. tubing is part number 290 0072-100.

Working pressures are calculated from burst testing using a 3:1 safety factor. Application testing is recommended.

ID is the critical dimension for fittings application.

[B] Limited stock item; lead times and minimums may apply – call for details.

Custom Capabilities

Cut Pieces

Size

Color

Custom Layline

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.