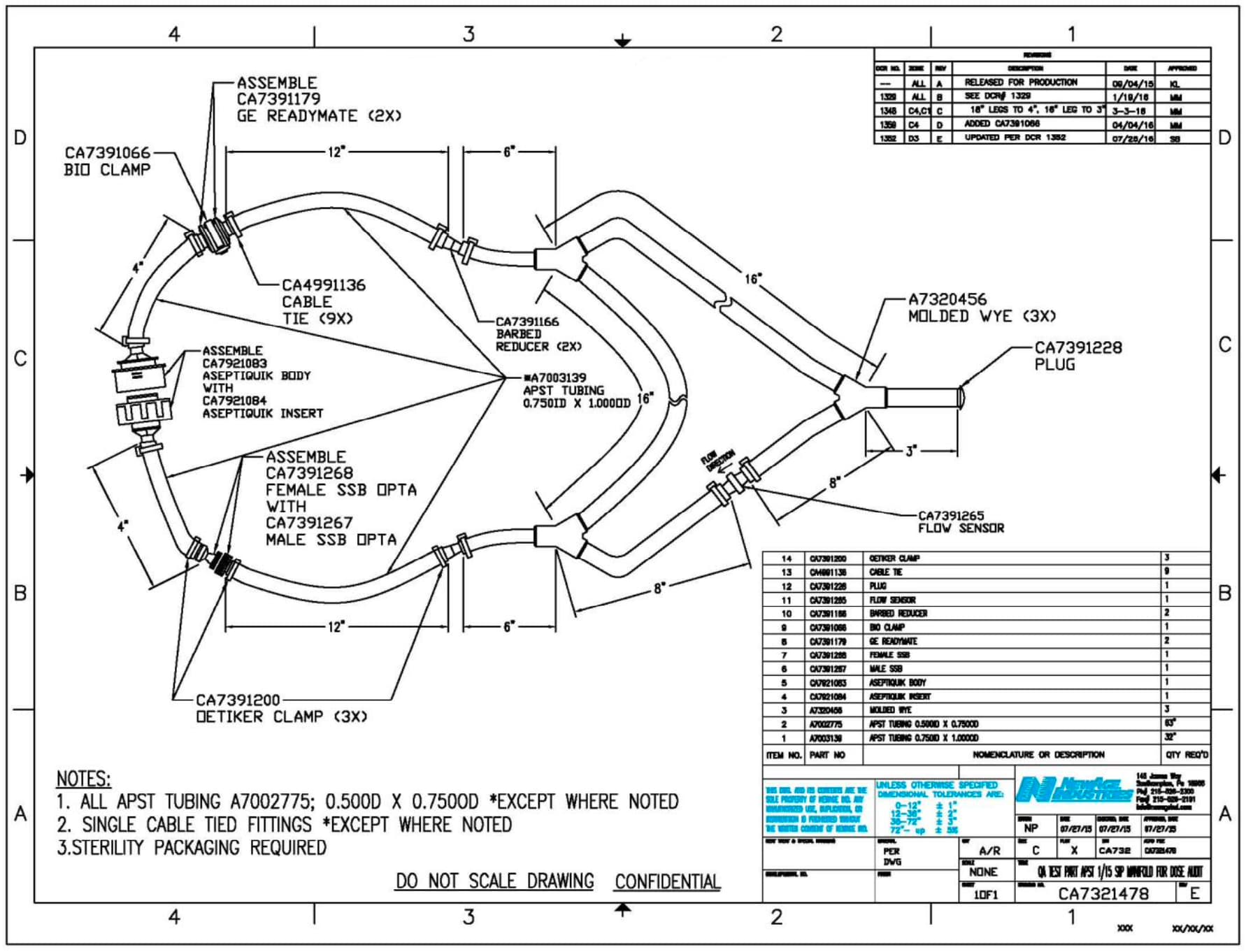

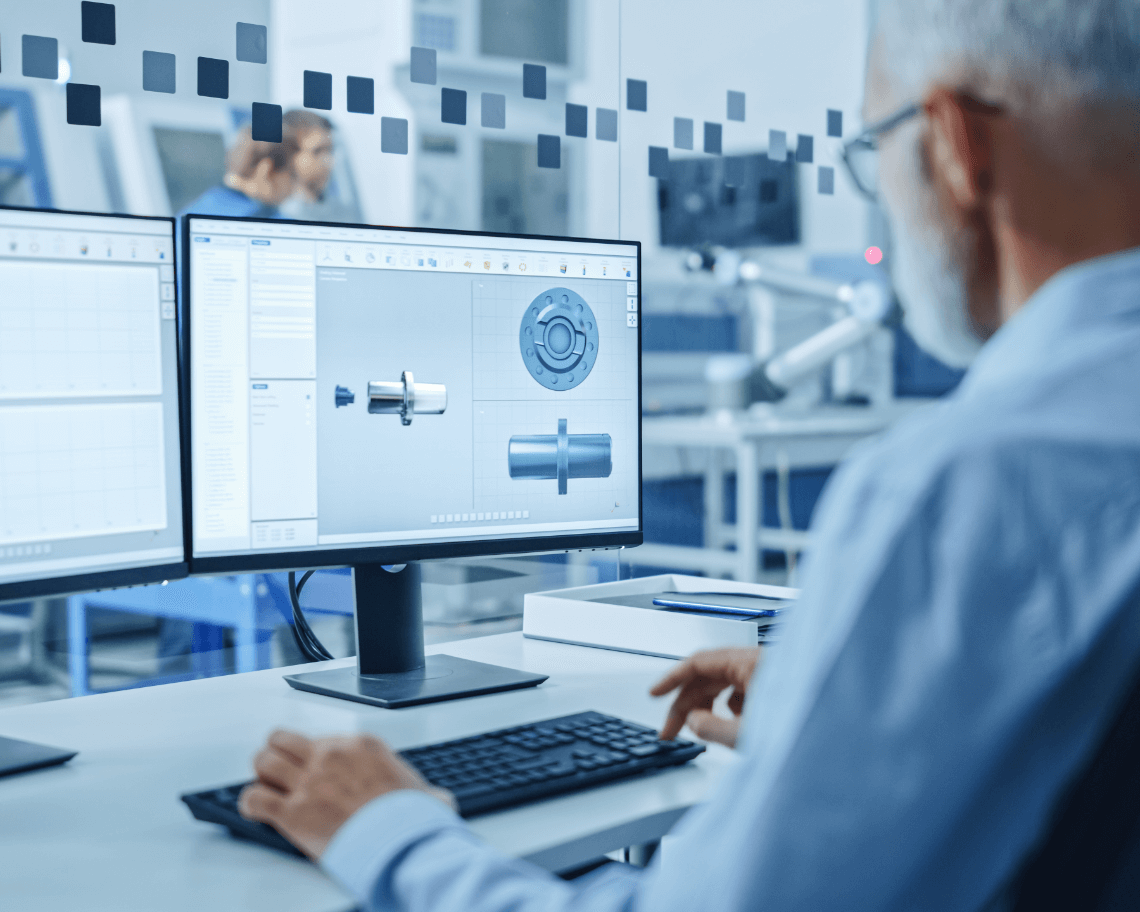

NewAge Industries has increased its engineering capabilities with the aim of providing better and faster services to our customers.

NewAge’s engineering team currently consists of applications engineers, design and test engineers, engineering project and process managers and tooling engineers. Their technical experience combined with a broad range of engineering backgrounds gives our team the expertise necessary to meet the needs of the industry.