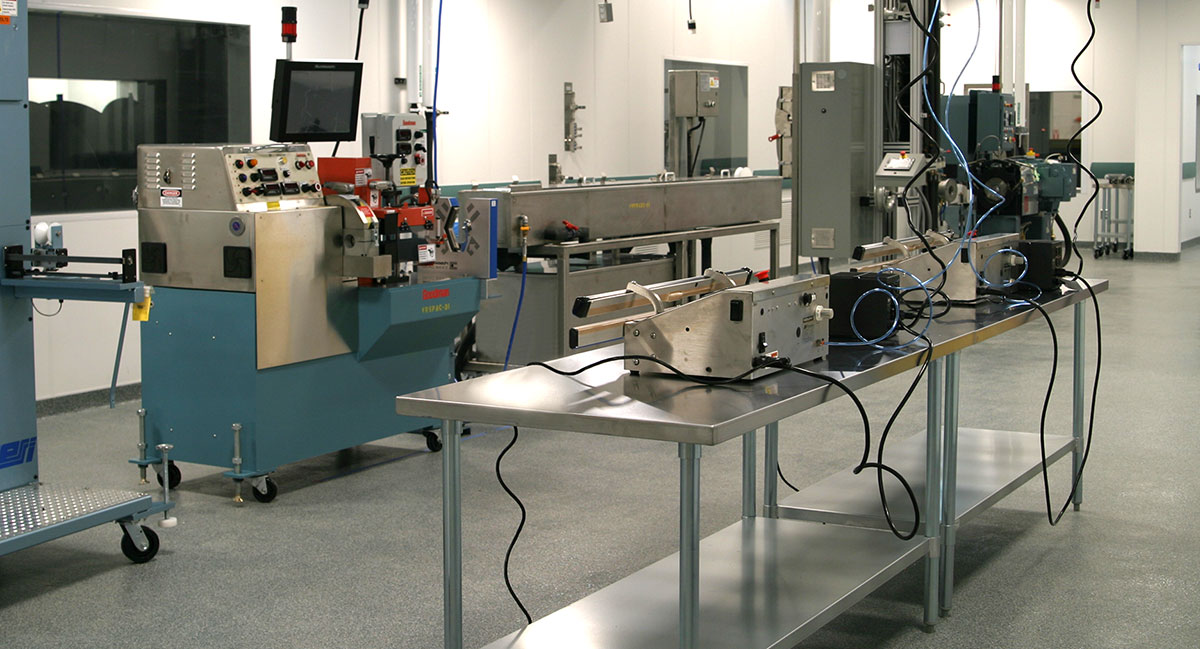

Tubing extrusion equipment for NewAge-AdvantaPure’s AdvantaSil® silicone tubing and reinforced hose and for AdvantaFlex® TPE tubing is being assembled in three of the seven new clean room manufacturing suites at our Warrington facility. The remaining four clean rooms are undergoing final HVAC and electrical work and will soon be tested for air quality.

AdvantaSil APST platinum-cured silicone tubing will be manufactured on the equipment shown above. Machinery includes not only the extruder but laser monitors for tubing dimensions, coilers, and packaging equipment.

This new mill will be used to process raw silicone prior to tubing production.

The application of braid material for our AdvantaSil APSH reinforced silicone hose will take place in this clean room.

An additional silicone tubing manufacturing room will be ready for air quality tests soon.

Other portions of the facility, such as break rooms and storage areas, have been constructed and are ready for team members and products.

If you have questions about our plans and progress, our staff is available. Call us at 215-526-2300 or contact us by e-mail at info@newageindustries.com.