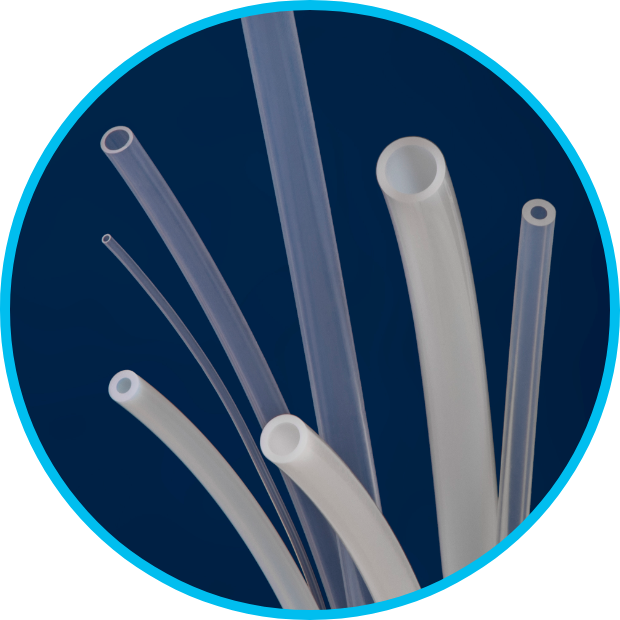

PTFE, FEP & PFA

Fluoropolymer Tubing

Features

- Chemically inert; low permeability

- Lowest coefficient of friction of any solid material

- Excellent electrical and weathering properties; non-flammable

- Made without plasticizer which can leach into critical streams

- Free of animal derived components

- Raw materials are FDA and USP Class VI compliant

- REACH and RoHS compliant

- PTFE is free of BPA, phthalates and latex

- FEP and PFA are free of conflict minerals

- Ultra-high-purity grades available for the semiconductor industry (FEP and PFA only)

Applications

Adhesives & Hot Glue Delivery • Chemical Transfer • Corrosives • Cryogenics • Deionized Water Transfer • Food & Beverage Processing • Industrial Laboratory Uses • Lighting Covers • Paint Spray Systems • Pure Water & Fluid Systems • Sight Glass (FEP) • Solvent Transfer • Water Sampling • Wire Insulation

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore D

Tensile Strength, psi

Elongation at Break, %

Brittle Temperature, °F

Max. Continuous Op. Temp., °F

50-65

2000-3000

200-450

<-450

500

57-60

4000

400

<-450

400

60

4200

400

<-450

500

Notes

PTFE (Polytetrafluoroethylene) a fluorocarbon-based polymer, is a resin supplied in powdered form, which is mixed, preformed, and extruded into a paste, and then finally tubing. PTFE tubing can be used in a wide variety of applications due to its high chemical resistance, high and low temperature capability, resistance to weathering, electrical and thermal insulation, gas and vapor permeability properties and lowest coefficient of friction of any solid material. The tubing is translucent white in color.

FEP (Fluorinated Ethylene Propylene) resin is pelletized for its hot-melt extrusion process. FEP tubing is known for its gas and vapor permeability properties and excellent UV transmission ratings. While very similar in composition to PTFE, there are a few notable differences. FEP has a lower heat shrink temperature and is clearer and more flexible than PTFE.

PFA (Perfluoroalkoxy) resin, like FEP, belongs to a class of melt-processible fluoroplastics. PFA tubing is also known for its gas and vapor permeability properties and excellent UV transmission ratings. It is similar in composition to FEP but has better heat resistance and a smoother surface. It, too, is clearer and more flexible than PTFE.

Almost totally inert, Fluoropolymer can be used with virtually all industrial solvents, chemicals, and corrosive materials, even at elevated temperatures. It does, however, react with fluorine, molten sodium hydroxide, and molten alkali metals.

Fluoropolymer Tubing can be steam or chemically sterilized in-line with any industrial cleaner, solvent, or sterilizing method.

Fluoropolymer’s non-stick property allows transport of viscous, sticky materials without line clogging. It also offers outstanding aging resistance.

PTFE’s translucent white color will vary naturally from lot to lot, however, the quality and physical properties do not change. FEP & PFA are clearer and can be heat sealed and heat bonded.

Permanent color striping, etching, and longer-than-listed lengths are available through minimum order. Polyethylene- jacketed, thin-wall fluoropolymer tubing, for low-cost purity, is also available through minimum order — call for details.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

PTFE Tubing

| Part Number | Note | Material | ID | OD | Wall | Available Lengths (ft.) | Working PSI (at 73°F) | Bend Radius (in.) | Bend Radius (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 3000074 | Fluoropolymer PTFE | .031 (1/32) | .063 (1/16) | .016 | 100 | 412 | 1/2 | ||

| 3000151 | Fluoropolymer PTFE | .031 (1/32) | .094 (3/32) | .030 | 100 | 390 | 1/2 | ||

| 3000228 | Fluoropolymer PTFE | .063 (1/16) | .125 (1/8) | .030 | 50, 100 | 290 | 1/2 | ||

| 3000382 | Fluoropolymer PTFE | .094 (3/32) | .156 (5/32) | .030 | 50, 100 | 220 | 5/8 | ||

| 3000459 | Fluoropolymer PTFE | .125 (1/8) | .188 (3/16) | .030 | 50, 100 | 180 | 3/4 | ||

| 3000536 | Fluoropolymer PTFE | .125 (1/8) | .250 (1/4) | .063 (1/16) | 50, 100 | 290 | 1/2 | ||

| 3000690 | Fluoropolymer PTFE | .188 (3/16) | .250 (1/4) | .030 | 50, 100 | 130 | 1 | ||

| 3000767 | Fluoropolymer PTFE | .188 (3/16) | .313 (5/16) | .063 (1/16) | 50, 100 | 222 | 7/8 | ||

| 3000844 | Fluoropolymer PTFE | .250 (1/4) | .313 (5/16) | .030 | 50, 100 | 100 | 2-1/4 | ||

| 3000921 | Fluoropolymer PTFE | .250 (1/4) | .375 (3/8) | .063 (1/16) | 25, 50, 100 | 180 | 1 | ||

| 3000998 | Fluoropolymer PTFE | .313 (5/16) | .375 (3/8) | .030 | 25, 50, 100 | 80 | 2-3/4 | ||

| 3001152 | Fluoropolymer PTFE | .375 (3/8) | .438 (7/16) | .030 | 25, 50, 100 | 70 | 4 | ||

| 3001229 | Fluoropolymer PTFE | .375 (3/8) | .500 (1/2) | .063 (1/16) | 25, 50, 100 | 130 | 2-1/4 | ||

| 3001306 | Fluoropolymer PTFE | .438 (7/16) | .500 (1/2) | .030 | 25, 50, 100 | 60 | 4 | ||

| 3001460 | Fluoropolymer PTFE | .500 (1/2) | .563 (9/16) | .030 | 25, 50, 100 | 55 | 5 | ||

| 3001537 | Fluoropolymer PTFE | .500 (1/2) | .625 (5/8) | .063 (1/16) | 25, 50, 100 | 100 | 3 | ||

| 3001614 | Fluoropolymer PTFE | .563 (9/16) | .625 (5/8) | .030 | 25, 50, 100 | 50 | 5-1/2 | ||

| 3001845 | Fluoropolymer PTFE | .625 (5/8) | .750 (3/4) | .063 (1/16) | 25, 50, 100 | 80 | 6 | ||

| 3010175 | Fluoropolymer PTFE | 2mm | 4mm | 1mm | 50, 100 | 290 | 13 | ||

| 3010350 | Fluoropolymer PTFE | 4mm | 6mm | 1mm | 50, 100 | 180 | 25 | ||

| 3010525 | Fluoropolymer PTFE | 6mm | 8mm | 1mm | 50, 100 | 130 | 51 | ||

| 3010700 | Fluoropolymer PTFE | 8mm | 10mm | 1mm | 25, 50, 100 | 100 | 64 | ||

| 3010875 | Fluoropolymer PTFE | 10mm | 12mm | 1mm | 50, 100 | 80 | 76 | ||

| 3011050 | [B] | Fluoropolymer PTFE | 12mm | 14mm | 1mm | 50, 100 | 60 | 89 |

[B] Limited stock item; lead times and minimums may apply –call for details.

I.D. and O.D. dimensions are NOMINAL. Wall dimension is REFERENCE.

Sold by standard coil length only.

Working pressures are calculated from burst testing using a 4:1 safety factor. Application testing is recommended.

Add length suffix to part number when ordering. Example: 100 ft. of 1/32″ I.D. x 1/16″ O.D. tubing is part number 300 0074-100.

NOTE: Orders for 50 ft. lengths of PTFE tubing may be filled with a maximum of two lengths of product totaling 50 ft. Orders for 100 ft. lengths of PTFE tubing may be filled with a maximum of three lengths of product totaling 100 ft.

OD is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

Size

Color

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.

Specifications

FEP Tubing

| Part Number | Note | Material | ID | OD | Wall | Available Lengths (ft.) | Working PSI (at 73°F) | Bend Radius (in.) | Bend Radius (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 3100090 | Fluoropolymer FEP | .063 (1/16) | .125 (1/8) | .030 | 50, 100 | 445 | 1/2 | ||

| 3100167 | Fluoropolymer FEP | .063 (1/16) | .188 (3/16) | .063 (1/16) | 50, 100 | 612 | 1/2 | ||

| 3100244 | Fluoropolymer FEP | .094 (3/32) | .156 (5/32) | .030 | 50, 100 | 357 | 1/2 | ||

| 3100321 | Fluoropolymer FEP | .125 (1/8) | .188 (3/16) | .030 | 50, 100 | 296 | 3/4 | ||

| 3100398 | Fluoropolymer FEP | .125 (1/8) | .250 (1/4) | .063 (1/16) | 50, 100 | 460 | 1 | ||

| 3100552 | Fluoropolymer FEP | .188 (3/16) | .250 (1/4) | .030 | 50, 100 | 223 | 1-1/2 | ||

| 3100629 | Fluoropolymer FEP | .188 (3/16) | .313 (5/16) | .063 (1/16) | 50, 100 | 368 | 1-1/2 | ||

| 3100706 | Fluoropolymer FEP | .250 (1/4) | .313 (5/16) | .030 | 50, 100 | 178 | 1-3/4 | ||

| 3100783 | Fluoropolymer FEP | .250 (1/4) | .375 (3/8) | .063 (1/16) | 25, 50, 100 | 307 | 1 | ||

| 3100860 | Fluoropolymer FEP | .313 (5/16) | .375 (3/8) | .030 | 25, 50, 100 | 148 | 2-1/2 | ||

| 3101014 | Fluoropolymer FEP | .375 (3/8) | .438 (7/16) | .030 | 50, 100 | 127 | 3-1/2 | ||

| 3101091 | Fluoropolymer FEP | .375 (3/8) | .500 (1/2) | .063 (1/16) | 25, 50, 100 | 230 | 2 | ||

| 3101168 | Fluoropolymer FEP | .438 (7/16) | .500 (1/2) | .030 | 25, 50, 100 | 111 | 6 | ||

| 3101322 | Fluoropolymer FEP | .500 (1/2) | .563 (9/16) | .030 | 25, 50, 100 | 89 | 12 | ||

| 3101399 | Fluoropolymer FEP | .500 (1/2) | .625 (5/8) | .063 (1/16) | 25, 50, 100 | 184 | 3 | ||

| 3101707 | Fluoropolymer FEP | .625 (5/8) | .750 (3/4) | .063 (1/16) | 25, 50, 100 | 153 | 6 | ||

| 3101938 | [B] | Fluoropolymer FEP | .750 (3/4) | .830 | .040 | 10 Straight | 74 | 8 | |

| 3102015 | Fluoropolymer FEP | .750 (3/4) | .875 (7/8) | .063 (1/16) | 5, 10 Straight | 132 | 12 | ||

| 3102169 | Fluoropolymer FEP | .875 (7/8) | 1.000 | .063 (1/16) | 5, 10 Straight | 115 | 22 | ||

| 3102246 | [B] | Fluoropolymer FEP | 1.000 | 1.100 | .050 | 5, 10 Straight | 75 | 26 | |

| 3102323 | Fluoropolymer FEP | 1.000 | 1.125 (1 1/8) | .063 (1/16) | 5, 10 Straight | 75 | 24 | ||

| 3102477 | [B] | Fluoropolymer FEP | 1.250 (1-1/4) | 1.375 (1-3/8) | .063 (1/16) | 5, 10 Straight | 70 | 30 | |

| 3102631 | [B] | Fluoropolymer FEP | 1.500 (1-1/2) | 1.625 (1-5/8) | .063 (1/16) | 5 | 64 | 36 | |

| 3110177 | Fluoropolymer FEP | 2mm | 4mm | 1mm | 50, 100 | 464 | 38 | ||

| 3110352 | Fluoropolymer FEP | 4mm | 6mm | 1mm | 50, 100 | 309 | 44 | ||

| 3110527 | Fluoropolymer FEP | 6mm | 8mm | 1mm | 50, 100 | 232 | 64 | ||

| 3110702 | Fluoropolymer FEP | 8mm | 10mm | 1mm | 25, 50, 100 | 186 | 70 | ||

| 3110877 | Fluoropolymer FEP | 10mm | 12mm | 1mm | 50, 100 | 155 | 102 | ||

| 3111052 | Fluoropolymer FEP | 12mm | 14mm | 1mm | 50, 100 | 119 | 305 |

[B] Limited stock item; lead times and minimums may apply –call for details.

Sold by standard coil length only.

I.D. dimension is REFERENCE.

Working pressures are calculated from burst testing using a 3:1 safety factor. Application testing is recommended.

Add length suffix to part number when ordering. Example: 50 ft. of 1/16″ I.D. x 1/8″ O.D. tubing is part number 310 0090-50.

All FEP lengths are supplied in single-section packages.

OD is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

Size

Color

Heat Form

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.

Specifications

PFA Tubing

| Part Number | Note | Material | ID | OD | Wall | Available Lengths (ft.) | Working PSI (at 73°F) | Bend Radius (in.) | Bend Radius (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 3200176 | Fluoropolymer PFA | .063 (1/16) | .125 (1/8) | .030 | 50, 100 | 449 | 1/2 | ||

| 3200330 | Fluoropolymer PFA | .094 (3/32) | .156 (5/32) | .030 | 50, 100 | 360 | 1/2 | ||

| 3200407 | Fluoropolymer PFA | .125 (1/8) | .188 (3/16) | .030 | 50, 100 | 299 | 3/4 | ||

| 3200484 | Fluoropolymer PFA | .125 (1/8) | .250 (1/4) | .063 (1/16) | 50, 100 | 464 | 1/2 | ||

| 3200561 | Fluoropolymer PFA | .188 (3/16) | .250 (1/4) | .030 | 50, 100 | 225 | 1 | ||

| 3200715 | Fluoropolymer PFA | .250 (1/4) | .313 (5/16) | .030 | 50, 100 | 179 | 1-3/4 | ||

| 3200792 | Fluoropolymer PFA | .250 (1/4) | .375 (3/8) | .063 (1/16) | 25, 50, 100 | 310 | 1 | ||

| 3200869 | Fluoropolymer PFA | .313 (5/16) | .375 (3/8) | .030 | 50, 100 | 150 | 2-1/2 | ||

| 3201100 | Fluoropolymer PFA | .375 (3/8) | .500 (1/2) | .063 (1/16) | 25, 50, 100 | 310 | 1 | ||

| 3201331 | Fluoropolymer PFA | .500 (1/2) | .563 (9/16) | .030 | 25, 100 | 75 | 12 | ||

| 3201408 | [B] | Fluoropolymer PFA | .500 (1/2) | .625 (5/8) | .063 (1/16) | 25, 50, 100 | 186 | 3 | |

| 3201716 | Fluoropolymer PFA | .625 (5/8) | .750 (3/4) | .063 (1/16) | 25, 50, 100 | 155 | 6 | ||

| 3210354 | Fluoropolymer PFA | 4mm | 6mm | 1mm | 50, 100 | 312 | 44 | ||

| 3210529 | Fluoropolymer PFA | 6mm | 8mm | 1mm | 50, 100 | 234 | 64 | ||

| 3210704 | Fluoropolymer PFA | 8mm | 10mm | 1mm | 25, 50, 100 | 187 | 70 | ||

| 3210879 | Fluoropolymer PFA | 10mm | 12mm | 1mm | 50, 100 | 156 | 102 |

[B] Limited stock item; lead times and minimums may apply –call for details.

Sold by standard coil length only.

I.D. dimension is REFERENCE.

Working pressures are calculated from burst testing using a 3:1 safety factor. Application testing is recommended.

Add length suffix to part number when ordering. Example: 25 ft. of 5/8″ I.D. x 3/4″ O.D. tubing is part number 320 1716-25.

All PFA lengths are supplied in single-section packages..

OD is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

Size

Color

Heat Form

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.