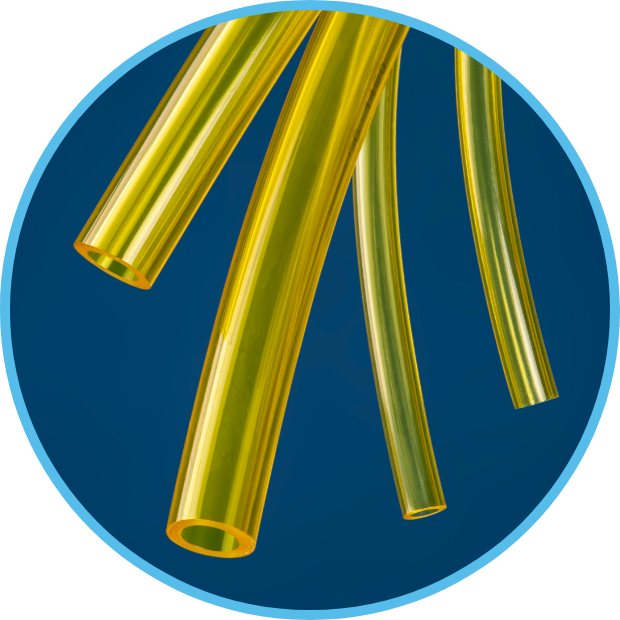

Clearflo® Fuel & Oil Grade PVC Tubing

Features

- Formulated to extend tubing life in fuel and oil applications

- Handles a wide variety of fuels, oils, chemicals, gases and liquids

- Mirror-smooth surfaces provide outstanding flow characteristics

- Lightweight yet tough and abrasion resistant

- As flexible as rubber

- Raw material meets UL94 HB burn rating

- BPA free

- RoHS compliant

Applications

Fuel & Oil Lines • Air & Gas Lines • Chemical Lines • Instrumentation • Laboratory & Research • Material Handling • Protective Jacketing • Pump Feed & Discharge

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore A ±5

Tensile Strength, psi

Elongation at Break, %

Brittle Temperature

Max. Operating Temperature, °F

62

1980

730

-20

175

Notes

Transparent yellow, Fuel & Oil Grade CLEARFLO, was created to extend the working life of PVC tubing in fuel & oil applications. Gasoline and oils harden standard PVC over periods of intermittent use, but CLEARFLO FUEL & OIL is specially formulated to prevent hardening.

CLEARFLO clear plastic tubing is generally unaffected by most oxidizing and reducing agents. Diluted acids and alkalies have little effect, though if highly concentrated tend to make the tubing less pliable. If chemical resistance is of major concern, in-plant tests are suggested.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

| Part Number | Note | ID (in.) | OD (in.) | Wall (in.) | Available Lengths (ft.) | Working PSI (at 70°F) | Weight (lbs./100 ft.) |

|---|---|---|---|---|---|---|---|

| 1110032 | .125 (1/8) | .250 (1/4) | .063 (1/16) | 50 | 68 | 2.1 | |

| 1110067 | [B] | .188 (3/16) | .313 (5/16) | .063 (1/16) | 100 | 55 | 2.8 |

| 1110102 | .250 (1/4) | .375 (3/8) | .063 (1/16) | 50, 100 | 55 | 3.5 | |

| 1110172 | .500 (1/2) | .750 (3/4) | .125 (1/8) | 50 | 45 | 12.8 |

[B] Limited stock item; lead times and minimums may apply –call for details.

Add length suffix to part number when ordering. Example: 50 ft. of 1/8″ I.D. x 1/4″ O.D. tubing is part number 111 0032-50. Sold by standard coil length only.

Working pressures are calculated from burst testing using a 3:1 safety factor. Application testing is recommended.

ID is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

Size

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.