Fluoropolymers are versatile engineering materials, and since their discovery in 1938, have been used in nearly every field of modern industry, technology, and science. They’re recognized for their non-stick properties, broad range of heat and cold resistance, and usefulness involving a wide variety of chemicals, solvents, and corrosive materials.

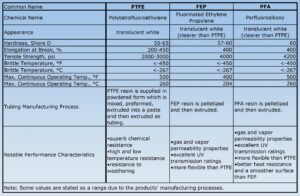

Several types of fluoropolymers are manufactured into tubing and fittings. While their general characteristics are similar, some properties vary depending on the formulation. The chart below provides a closer look at the types of fluoropolymer tubing available from NewAge Industries.

Other types of fluoropolymer materials include:

• PVDF (polyvinylidene fluoride)

• ETFE (ethylene tetrafluoroethylene)

• ECTFE (ethylene chlorotrifluoroethylene)

• PCTFE (polychlorotrifluoroethylene)

Fluoropolymers offer the lowest coefficient of friction of any solid material. The smooth surfaces of fluoropolymer tubing make it ideal for applications such as adhesive delivery, environmental sampling, and pure air and water systems.

Learn more about NewAge Industries’ fluoropolymer tubing and injection molded PFA compression fittings. In addition to straight tubing, we also offer formed & coiled parts in FEP and PFA tubing, corrugated FEP tubing (for increased bend radii) and convoluted PTFE tubing (for easier flush cleaning).

If you need fluropolymer tubing or have questions, phone us at 800-506-3924 or 215-526-2300, e-mail info@newageindustries.com, or use the Contact Us form below.